If you’ve ever wondered why powder coating lines produce such durable, high-quality finishes, the answer lies in electrostatic powder coating technology.

This process is at the heart of modern coating systems for automotive parts, metal furniture, agricultural equipment, and industrial enclosures. It’s cleaner, more efficient, and longer-lasting than traditional painting.

Now, we’ll explain what electrostatic powder coating is, how it works, and why it’s the preferred choice for industrial manufacturers.

What Is Electrostatic Powder Coating?

Electrostatic powder coating is a dry finishing process that uses an electrostatic charge to make powdered particles adhere to a metal surface.

Unlike liquid paint, which requires solvents, powder coating uses 100% solid particles that are sprayed directly onto the part.

Once applied, the coated part is baked in a curing oven, where the powder melts, flows, and chemically bonds to create a hard, durable finish.

How Does Electrostatic Powder Coating Work?

Here’s the step-by-step process inside a typical automatic powder coating line:

1. Pretreatment

Parts are cleaned, degreased, and sometimes chemically treated for better adhesion.

2. Electrostatic Charging

A spray gun applies an electric charge (usually 60–100 kV) to the powder particles.

3. Powder Attraction

The charged powder is attracted to the grounded metal part, covering even complex shapes.

4. Excess Powder Recovery

Overspray is collected in a powder recovery system and reused, reducing waste.

5. Curing

Parts enter a curing oven where heat melts and bonds the coating into a smooth, protective layer.

Why Electrostatic Powder Coating Works So Well

✅ Strong Adhesion

The electrostatic charge creates a uniform coating that clings tightly to the surface.

✅High Transfer Efficiency

Minimal waste—most of the powder ends up on the part.

✅ Uniform Coverage

Even coating thickness without drips or sags.

✅ Environmentally Friendly

No VOCs or solvents, and unused powder can be recycled.

✅ Durable Finish

Scratch-resistant, corrosion-resistant, and UV-stable, making it ideal for outdoor and industrial use.

What Equipment Is Needed for Electrostatic Powder Coating?

A complete electrostatic powder coating line typically includes:

Pretreatment Line

(Spray or dip system for cleaning and surface preparation)

Powder Spray Booth

Equipped with automatic or manual electrostatic spray guns

Powder Recovery System

To collect and reuse overspray powder

Conveyor System

To move parts through each section automatically

Curing Oven

Gas or electric oven for baking and bonding the coating

At Yantai Clear, we design manual, semi-automatic, and fully automatic systems, depending on your production needs.

Which Industries Use Electrostatic Powder Coating?

Electrostatic powder coating is widely used in:

Automotive industry → wheels, frames, bumpers

Agricultural machinery → tractors, metal housings

Metal furniture → shelves, chairs, cabinets

Architectural products → window frames, fences, gates

Electrical equipment → enclosures, switchgear cabinets

Any metal product that requires durability, corrosion protection, and attractive finishes can benefit from this process.

Advantages vs Liquid Painting

| Feature | Electrostatic Powder Coating | Liquid Painting |

| ——————— | ——————————– | ——————————- |

| VOC Emissions | Zero | High |

| Material Waste | Recyclable overspray | Lost overspray |

| Finish Durability | Strong & impact-resistant | Less durable |

| Operator Safety | Cleaner, no solvents | Requires solvent handling |

| Production Cost | Lower in the long run | Higher due to waste & touch-ups |

💡 Result: Electrostatic powder coating is greener, more efficient, and more durable—ideal for modern manufacturing.

Common Challenges & How to Avoid Them

Even electrostatic coating has challenges like Faraday cage effects or uneven coverage in corners.

Solutions include:

Adjusting KV voltage for complex shapes

Improving part grounding

Using manual touch-up guns for recessed areas

With the right powder coating booth design and training, these issues can be minimized.

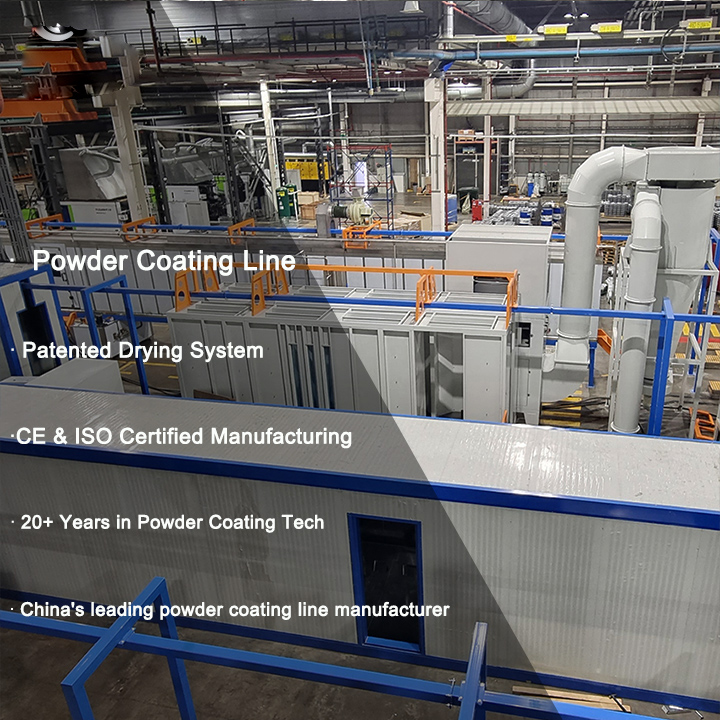

Yantai Clear: Experts in Electrostatic Powder Coating Lines

For over 20 years, Yantai Clear has helped factories build efficient electrostatic powder coating systems.

✅ Custom layouts to fit your factory space

✅ Energy-saving ovens that reduce operating costs

✅ Advanced spray booths with high recovery efficiency

✅ Full after-sales support and operator training

Whether you need a manual batch line for small parts or a fully automatic conveyorized line for mass production, we’ll deliver the most cost-effective solution.

Ready to Upgrade Your Coating Process?

Electrostatic powder coating is the future of industrial finishing—cleaner, stronger, and more cost-efficient than traditional paint.