Even the most advanced powder coating lines sometimes face quality issues. From poor adhesion to unexpected surface defects, these problems can reduce product lifespan, increase rework costs, and frustrate both operators and customers.

At Yantai Clear, we’ve worked with factories in industries like automotive, furniture, and agricultural machinery for more than 20 years. We’ve seen the same issues occur again and again—and we know exactly how to solve them.

Here’s a comprehensive troubleshooting guide to the 10 most common powder coating problems and how you can fix them.

1. Poor Adhesion to the Substrate

What it looks like: The coating easily peels off, scratches away, or doesn’t bond well.

Why it happens:

Inadequate surface cleaning before coating / Residual oil, rust, or dust on the part / Incorrect curing temperature

How to fix it:

Use a proper pretreatment line (degreasing, phosphating, rinsing) / Ensure parts are completely dry before coating / Verify oven temperature and curing time

2. Orange Peel Texture

What it looks like: A bumpy, uneven finish that resembles the surface of an orange.

Why it happens:

Powder applied too thickly / Improper gun settings / Over-curing or under-curing

How to fix it:

Maintain the correct spray distance and KV voltage / Use a powder coating line layout that ensures stable airflow / Adjust oven temperature profiles carefully

3. Pinholes or Small Craters

What it looks like: Tiny holes or bubbles in the cured coating.

Why it happens:

Moisture trapped in the substrate / Contaminants like oil or silicone / Outgassing from cast metal

How to fix it:

Pre-bake porous metals to release trapped gases / Ensure all parts are dry after pretreatment / Avoid handling parts with oily gloves

4. Thin or Uneven Coverage

What it looks like: Some areas have minimal coating while others look normal.

Why it happens:

Poor grounding of parts / Incorrect gun angle or movement / Faraday cage effect in corners

How to fix it:

Check grounding cables and hooks regularly / Spray from multiple angles / Use low KV settings for deep recesses

5. Faraday Cage Effect

What it looks like: Powder won’t reach corners, recesses, or sharp edges.

Why it happens:

Electric fields repel powder from tight spaces / High KV voltage makes it worse

How to fix it:

Lower the KV voltage for complex shapes / Use auxiliary manual touch-up guns / Adjust part hanging orientation

6. Color Mismatch or Inconsistent Gloss

What it looks like: Different parts have slightly different colors or gloss levels.

Why it happens:

Mixing different powder batches / Incorrect curing cycle / Contaminated spray booth

How to fix it:

Always use the same batch for one production run / Clean the powder spray booth before each color change / Follow the manufacturer’s curing specifications

7. Overbaking or Undercuring

What it looks like: Coating becomes too brittle (overbake) or soft (undercure).

Why it happens:

Oven temperature too high or too low

Conveyor speed too fast/slow

Uneven airflow inside the oven

How to fix it:

Calibrate your curing oven regularly

Use a temperature profiler to monitor heat

Adjust conveyor speed for proper dwell time

8. Contamination in the Coating

What it looks like: Dust, fibers, or particles embedded in the finish.

Why it happens:

Dirty spray booth filters / Poor factory ventilation / Operator clothing shedding fibers

How to fix it:

Use a powder recovery system with HEPA filters

Maintain cleanroom-like conditions near the booth

Train operators on proper handling

9. Excessive Powder Waste

What it looks like: High powder consumption and frequent booth cleaning.

Why it happens:

Poor transfer efficiency / Overspray not being recycled / Improper airflow in the booth

How to fix it:

Upgrade to an automatic powder coating booth with recovery system

Adjust gun settings for better efficiency

Install proper air balance in the booth

10. Edge Pull or Thin Coating on Sharp Edges

What it looks like: Coating is thinner at corners and edges, exposing bare metal.

Why it happens:

Electrostatic force pulls powder away from sharp areas

High film build elsewhere leaves less for edges

How to fix it:

Apply a second coat for edge protection

Reduce voltage during edge spraying

Use a primer coat before the main layer

Preventing Problems Before They Happen

Most coating problems come from improper pretreatment, incorrect equipment settings, or poor maintenance. Here’s how to prevent them:

Invest in a reliable pretreatment line – clean, rinse, and dry properly

Calibrate your curing oven every month

Train your operators to recognize early signs of defects

Work with experienced suppliers who can design a stable, efficient coating process

Yantai Clear: Your Partner for Trouble-Free Coating

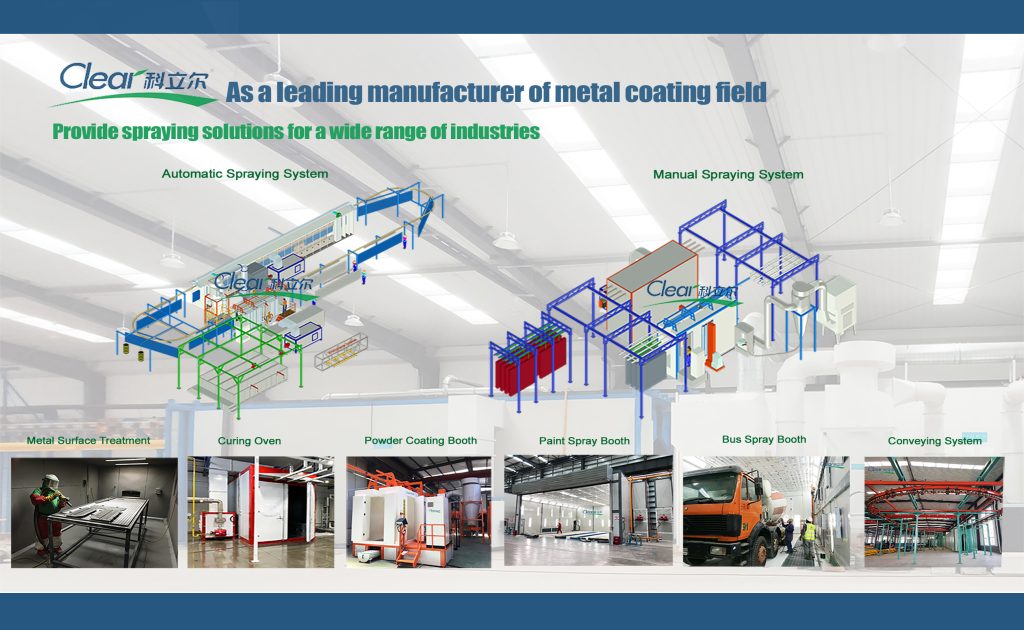

When you choose Yantai Clear, you get more than just equipment. You get:

✅ Custom-designed powder coating lines to fit your products

✅ Optimized spray booths and ovens for consistent quality

✅ Expert support and on-site training for your team

Don’t let coating defects slow down your production. We help you achieve perfect finishes with less waste and fewer problems.

Need Expert Help with Your Powder Coating Line?

If you’re struggling with these problems, or if you want to upgrade to a more reliable powder coating line, let’s talk.